Looking for a part? Check our stock list or leave a request!

Delivery of a Deutz SVB8M628

Over the years Cornerpoint is involved in many projects of engineering. Having a strong technical back-up from within our mother company Teus Vlot Diesel & Marine we are able to assist in many technical challenges that you might face on board.

Mid April we received the question for an engine replacement of a fishing vessel; time, updating/upgrading and off course cost were the main factors. The existing Deutz ME 6M628 had damage beyond repair. During operation owners noted that the existing engine was a bit light for the application. Therefore several scenarios of re-powering were checked.

An upgraded model of the 6M628 would give about 30% more horse power. The adaption on the vessel was very limited due to the fact that the propeller and gearbox could handle the 30% more power. However the cost of this engine was quite significant compared to the resulted upgrade of 30%.

Second option was a Deutz 8M628. This engine would give 80% more horse power. The propeller and gearbox needed to be changed and space had to be made in the engine room to fit the 2 extra cylinders on this engine. Luckily the propeller shaft was calculated to handle even this 80% more.

Third option we looked at were the available engines in the market at that stage. Due to time, a new engine was out of the question. However nowadays you can run into something suitable because of many new build projects are cancelled. At that stage we were able to offer 3 different suitable engine’s.

Owners preferred the idea of the 8M628 and further technical issues were discussed and solutions quoted. Our sales and technical engineers flew down and visited the vessel to thoroughly check suitability of the ship and all its systems. On such a refit with upgrading, all system have to be adapted to handle the 80% more output. So cooling, fuel supply, start-air supply, air supply and exhaust systems were measured on board and new plans were engineered to suit the engine. Mayor challenges were to find a suitable gearbox in reasonable time, to fit the existing CPP system on the new gearbox and to find a PTO-drive to replace the existing PTO drive for 4 clutch-able hydraulic pumps.

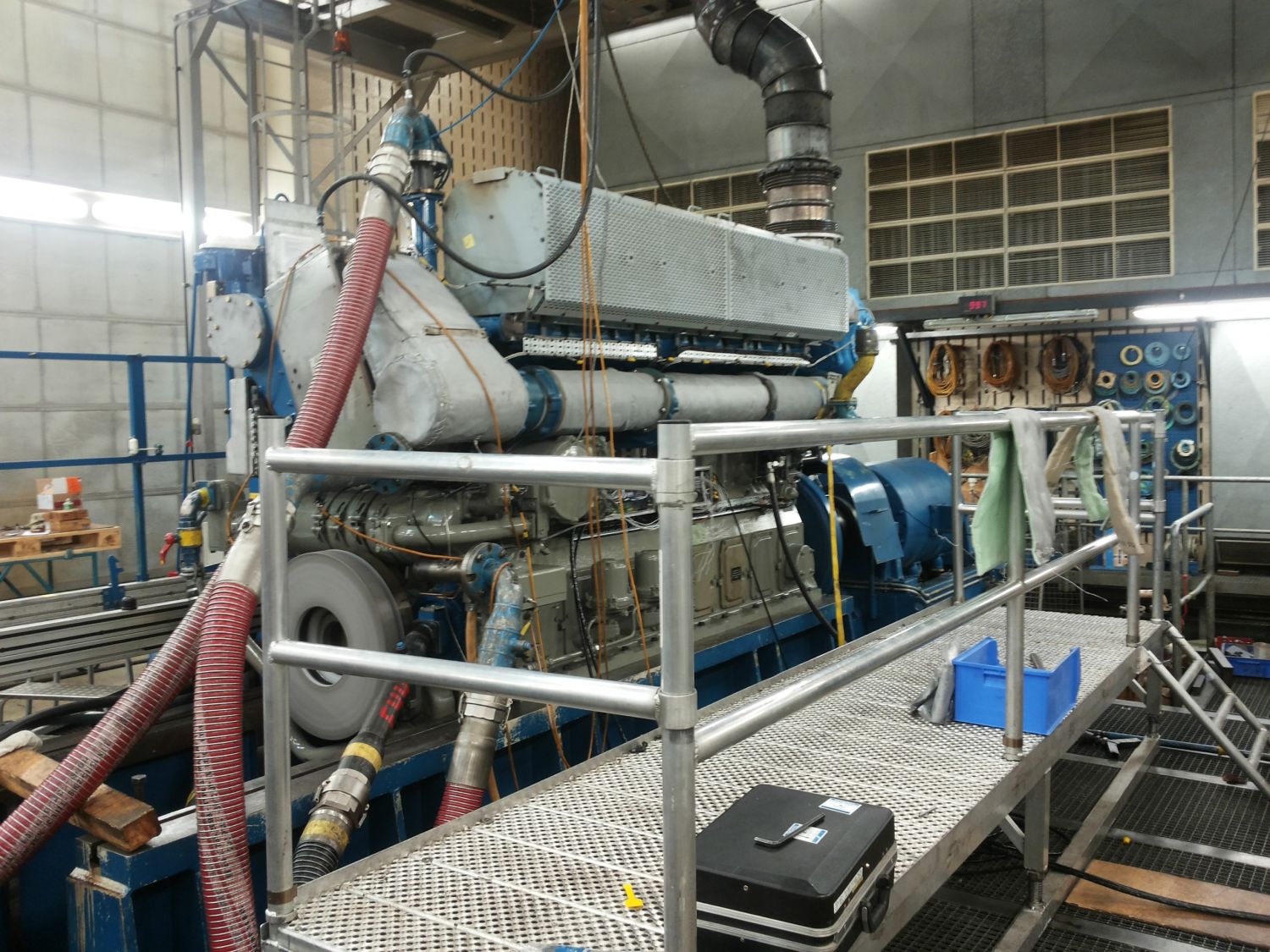

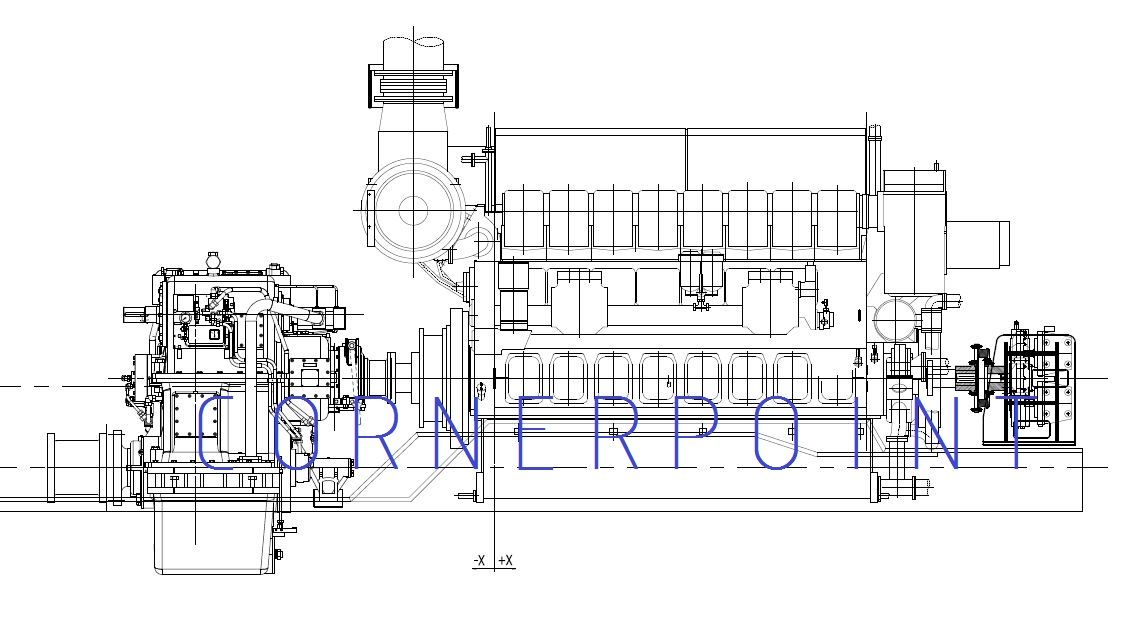

The Deutz 8M628 engine is a fully reconditioned engine, upgraded to the most modern execution complying with Tier II standard. Also the electronic control system is of the latest standard with future shore-connection possibility. Gearbox was found in an overstock of Wartsila and the PTO drive was supplied by Twin-disk Technodrive. Flexible elements from Vulkan were selected for connection of gearbox to main engine and for the PTO drive. The general arrangement drawing was made in house by our drawing engineer. See attached pictures of the set-up.

Based on the general arrangement we made an advise of how to change the engine base of the ships construction. This work could be carried out during the delivery time of all the items.

After readiness of the equipment Cornerpoint checked all technical aspects and fitted the all the flanges of the components on each other where possible. Pushed by time Cornerpoint has checked options to fly the whole engine and all its components (22 tons in total) to the installation yard. However a sharp price was given, owners decided that sea freight would be suitable. Cornerpoint took care of seaworthy packing of all the equipment and stowing into 2 containers.

Shipment is now on its way to the ship for installation.